Webmaster: Stansfeld, LLC. |

|

|

JANUARY 2012 MEETING

Wednesday, January 11, 2012 (1.0 PDH)

TECHNICAL PROGRAM

General Overview of Stabilization Application

Speaker: Mr. Don Show, Synteen Technical Fabrics, Inc., Lancaster, South Carolina, Tel. No. 800-796-8336

Mr. Don Show is currently the Vice President of Sales & Marketing at Synteen Technical Fabrics, Inc. He has earned a Business Administration Degree from the University of California. His 25 years of experience includes Geosynthetic Marketing and National Distribution. In 1999 he assisted in the startup of a new company in the manufacturing of Geogrids and High Strength Polyester Geotextiles. He works closely with DOTs, US COE, and other state and federal agencies for submittals of soil reinforcement product approvals. He is also responsible for reviewing specifications and recommending the appropriate product to meet the specification or suggest a functional equal.

PRESENTATION SUMMARY

To an audience of about 60 at the HESS Club, Mr. Don Show presented information on the use of geogrids and geotextiles. Mr. Show discussed the differences between geogrids and geotextiles and their uses and applications.

Geotextiles are typically a high strength technical fabric. The geotextiles are permeable and are often used where separation of materials is required. Geotextiles are placed within layers of soft or weak foundation soils to dramatically improve soil strength. The most common applications for geotextiles are found at soil slopes, levees, berms, pond and landfill stabilization, and embankments over soft or unstable subgrades.

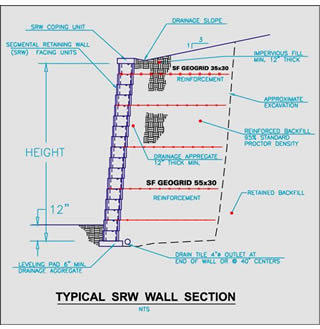

Geogrids tend to have larger openings that geotextiles and have different properties. Geogrids may be reinforced in a single direction (uniaxial) or provided strength reinforcing in two directions (biaxial). The installation of a biaxial geogrid provides lateral stability to unbound base courses. This soil confinement significantly improves the stress distribution of the soil materials. Synteen refers to this as the “snowshoe” effect. This effect is capable of spreading a concentrated load from traffic or overburden over a larger area. This increase in strength often permits a reduction in the subgrade base course thickness thereby reducing that cost of material.

Synteen uses a comparison method referred to as the Base Course Reduction (BCR) percentage for geogrid reinforced versus unreinforced aggregate thickness. The percentage reduction varies depending on the strength of supporting subgrade material.

Additional benefits are:

- Geotextiles and geogrids may be used in combination or alone

- The design life of the Synteen products in soil is estimated at 100 years.

- Individual lengths and product sizes can be produced for specific job requirements.

- Synteen offers both geogrid and geotextile products so they are a single source manufacturer.

- Geogrids lower deformations, improve the strength to weight ratio, and dramatically improve long term design strength

For additional information, contact Synteen at http://www.synteen.com/

To download a copy of Mr. Show’s slide presentation click here

|